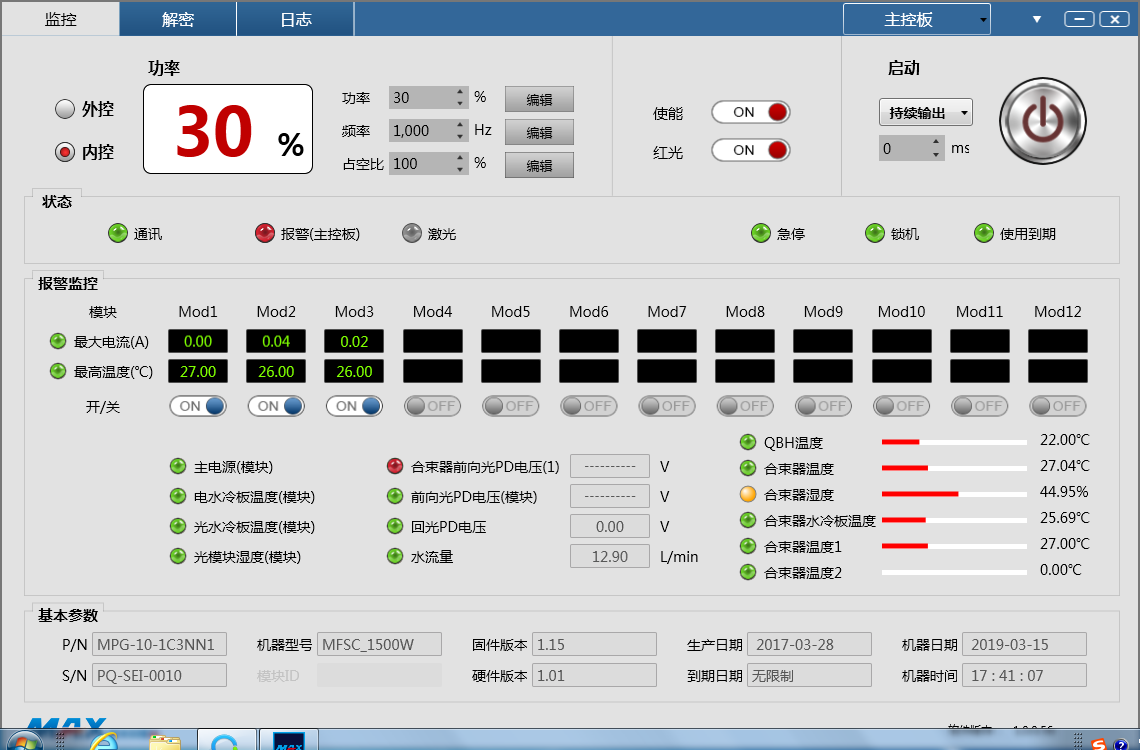

To facilitate users to monitor the operation status of the laser in real-time, control the light output of the laser, record the historical use status of the laser, and facilitate customers to troubleshoot equipment abnormalities promptly, Maxphotonics independently developed monitoring software supporting the laser. If the laser operation is abnormal, the monitoring software will send out a warning. Now we have summarized some common questions and attached answers.

1. Forward Light PD Alarm

Protection measures: The main power supply stops supplying power and the laser is turned off.

Possible cause: The PD inside the laser cannot detect the laser.

Solution:

1. Restart the laser without turning on the laser, and check if it has red beam. If there is no red beam, please contact our customer service;

2. If it has red beam, please check whether the relevant module can turn on the laser. Check whether the voltage output of the DC power supply of the module power supply is normal.

2. Strong Back-reflective Light Alarm

Protection measures: The main power supply stops supplying power and the laser is turned off.

Possible cause: The laser beam combining module has detected excessive back-reflective light.

Solution:

1. Check the laser focus position;

2. Check whether the material is placed horizontally;

3. Check whether the material is ultra-highly reflective material;

4. Check whether the thickness of the material exceeds the standard and cannot be cut through;

5. Turn off the laser, suspend use for 3-5 minutes, restart the laser, and turn on the laser.

3. Pump Source Temperature Alarm

Protection measures: The main power supply stops supplying power and the laser is turned off.

Possible cause: The temperature of the pump source of the laser module is too high.

Solution:

Turn off the laser, check whether the flow rate and temperature of the water cooler are normal and whether the water pipe is blocked.

After the inspection is complete, restart the laser and the laser returns to normal. If it fails to return to normal, please contact our customer service staff.

4. QBH Installation Alarm

Protection measures: The main power supply stops supplying power and the laser is turned off.

Possible cause: Poor contact between laser QBH output head contact point and cutting head contact point.

Solution: Turn off the laser, check the laser QBH output head and cutting head, and reinstall.

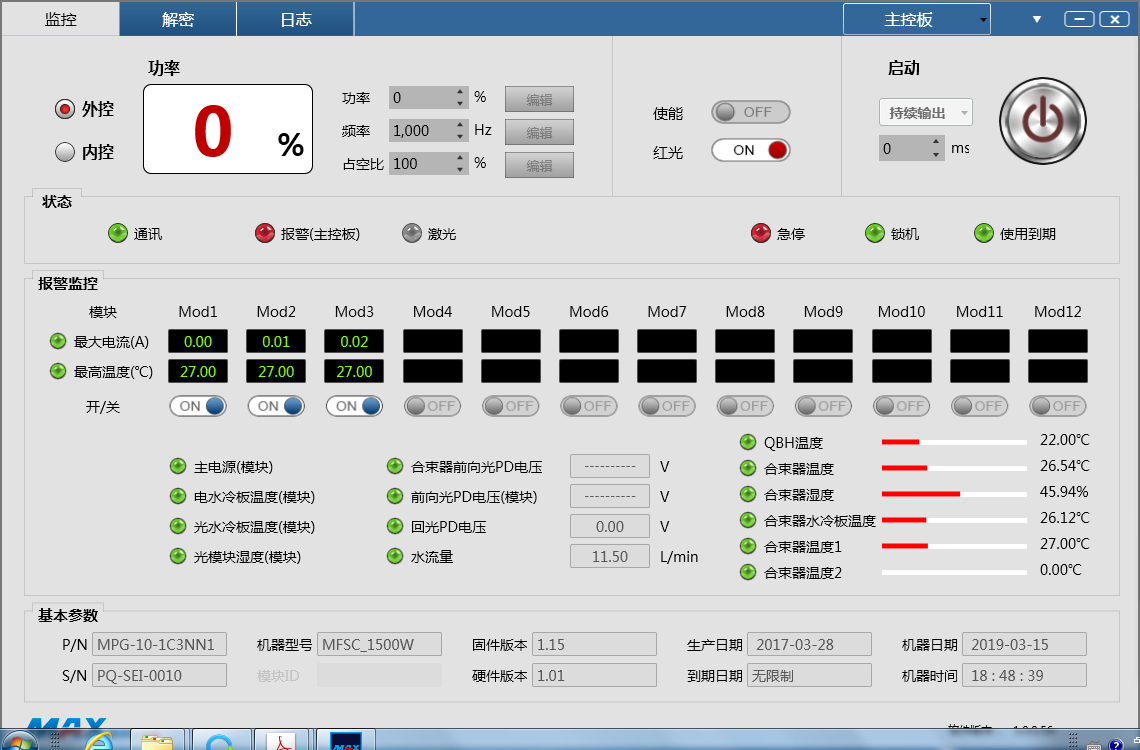

5. Emergency Stop Alarm

Protection measures: The main power supply stops supplying power and the laser is turned off.

Possible cause: The emergency stop switch was pressed.

Solution: The emergency stop switch returns to normal state and restart the laser.

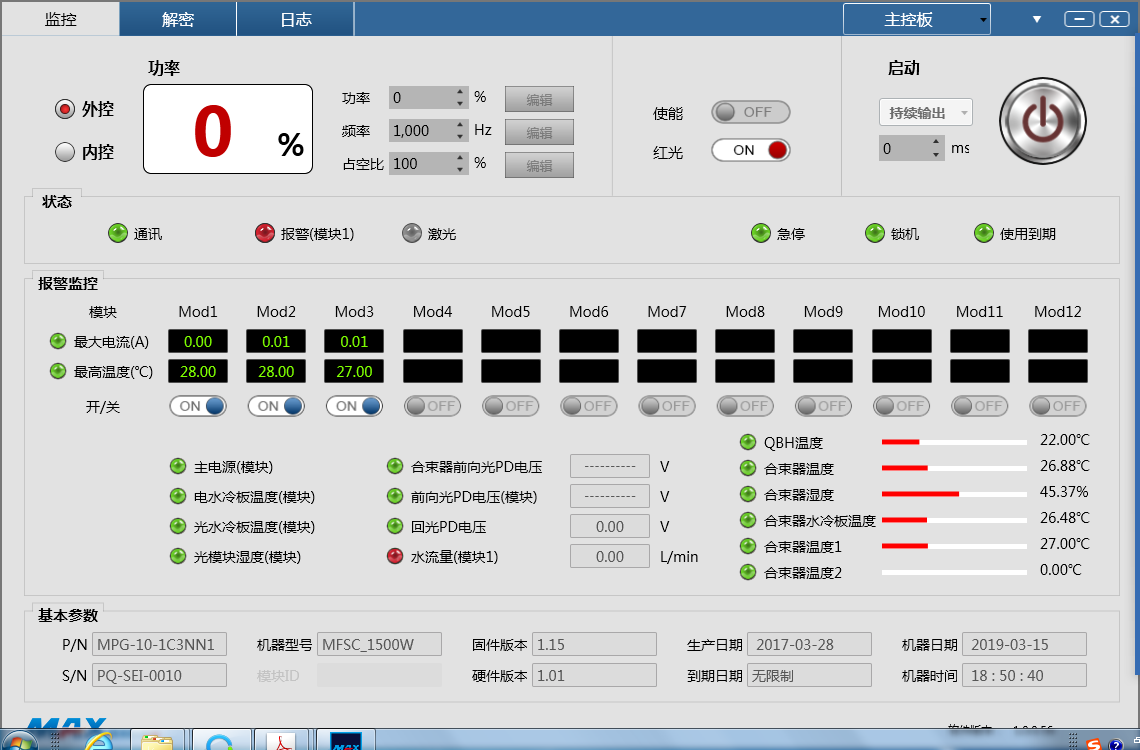

6. Water Flow Alarm

Protection measures: The main power supply stops supplying power and the laser is turned off.

Possible cause: The chiller is abnormal, resulting in reduced water flow.

Solution: Turn off the laser, check whether the flow rate and temperature of the water cooler are normal and whether the water pipe is blocked.

After the inspection is complete, restart the laser and the laser returns to normal.

7. Abnormal Communication Alarm

Protection measures: The main power supply stops supplying power and the laser is turned off.

Possible cause: There is no signal transmission between the single module communication line and the main module.

Solution:

1. Check whether the signal cable connecting the single module and the main module is loose;

2. Check whether the single module can be powered on normally, whether it has red beam, and whether the auxiliary power supply voltage output works normally.

8. Maximum Current Alarm

Protection measures: The main power supply stops supplying power and the laser is turned off.

Possible cause: The working current of the single-module pump source exceeds the maximum limit.

Solution:

1. After the laser is turned off and restarted, check whether it is normal;

2. If the maximum current alarm still occurs, the drive MOS tube in a single module may break down. You need to turn off the laser immediately and contact our customer service.

9. The Water Cooling Plate of The Electric Module Alarm

Protection measures: The main power supply stops supplying power and the laser is turned off.

Possible cause: The temperature of the water cooling plate in the electrical module is too high.

Solution:

Turn off the laser, check whether the flow rate and temperature of the water cooler are normal and whether the water pipe is blocked. After the inspection is complete, restart the laser and the laser returns to normal. If it fails to return to normal, please contact our customer service staff.

10. Temperature Alarm of Water Cooling Plate of Beam Combiner

Protection measures: the main power supply stops supplying power and the laser is turned off;

Possible cause: The temperature of the water cooling plate in the beam combiner is too high.

Solution:

Turn off the laser, check whether the flow rate and temperature of the water cooler are normal and whether the water pipe is blocked. After the inspection is complete, restart the laser and the laser returns to normal. If it fails to return to normal, please contact our customer service staff.