The material is irradiated with a high power density laser beam so that the material is quickly heated to a molten or vaporized state, and as the beam moves toward the material, a slit or weld having a narrow width is formed. Laser processing is highly efficient, high energy density and soft, making it the perfect choice for all industries, in terms of accuracy, speed and efficiency.

In the process of absorption and conversion of laser processed material into thermal energy, different power densities cause different changes on the surface of the material. As the temperature increases, the material undergoes phase change, melting, vaporization and other state changes, and different states and changes to the absorption of laser has a great impact.

In the processing of high-reflective materials, whether cutting or welding, it is a traditional problem in the field of laser processing. Almost all the concerns of all customer manufacturers: Can your equipment process high reflective materials?

The following four methods quickly teach you what is high reflective material:

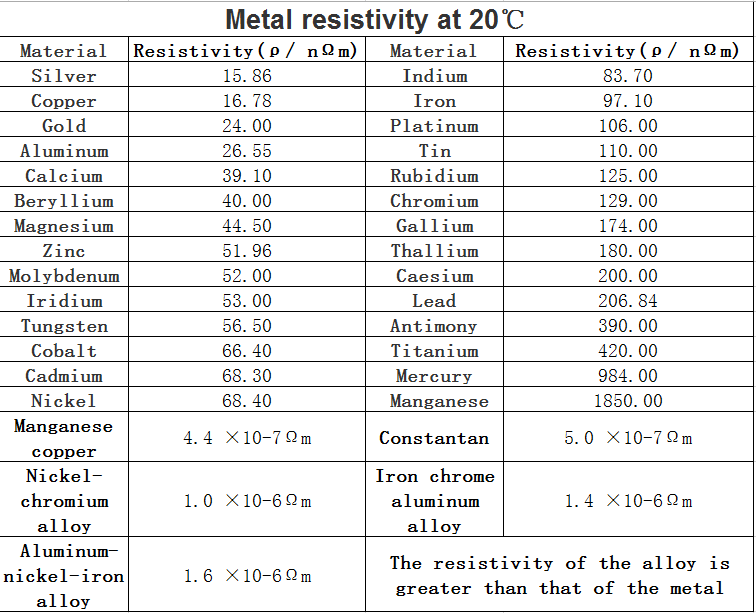

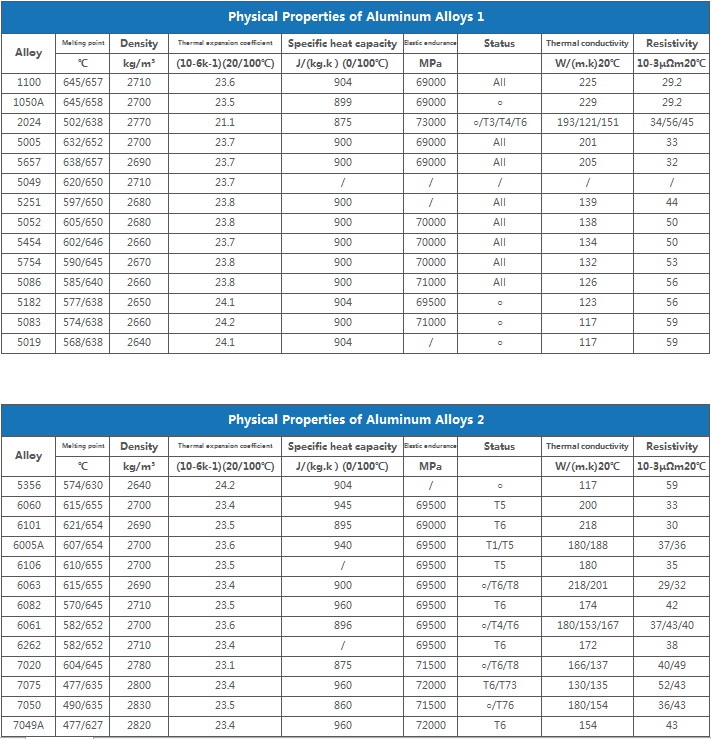

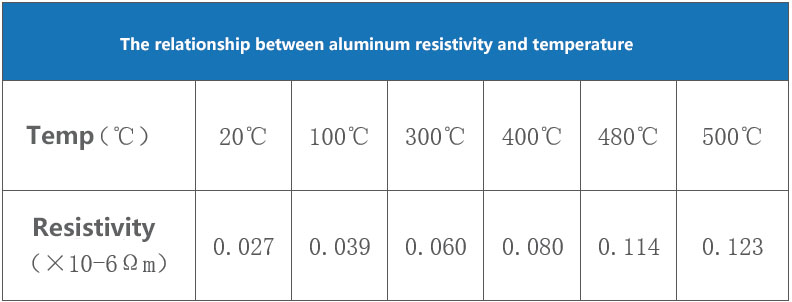

Method 1: Determine by resistivity

In general, the lower the resistivity of the material, the lower the absorption rate of the laser (high reflective); the higher the resistivity, the higher the absorption rate.

It is worth noting that, for example, the electrical resistivity of different grades of aluminum alloys is not the same. For commonly used steels: resistivity is graded in carbon steel, ferritic, martensitic, and austenitic stainless steels (eg, resistivity: Q235 carbon steel <410 stainless steel <405 stainless steel <304 stainless steel).

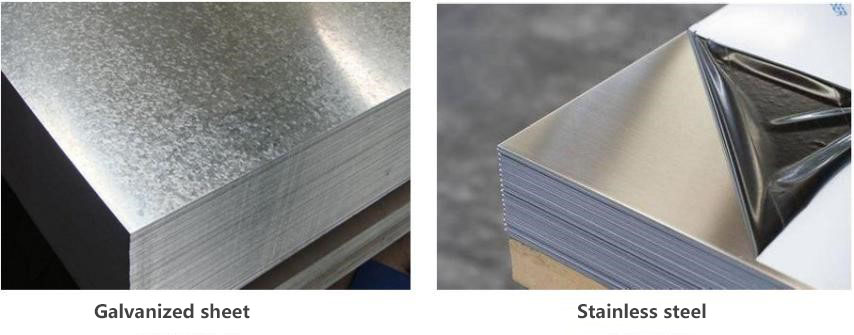

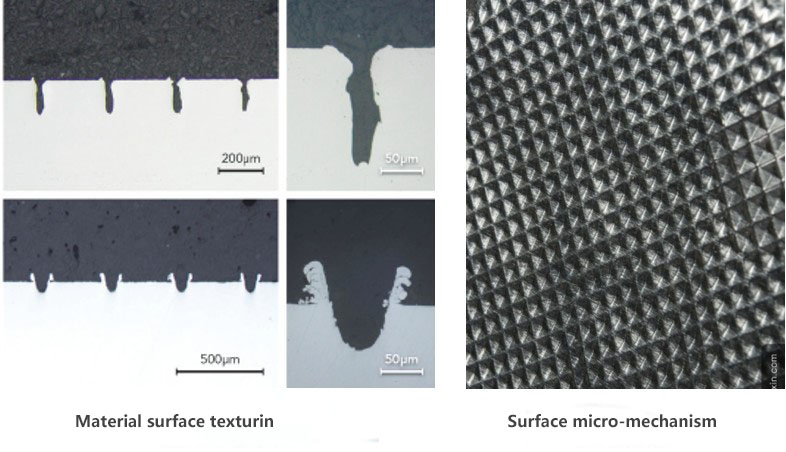

Method 2: Judging by surface structure

The smoother the surface of the material, the lower the absorption of the laser; if it is sufficiently smooth (even stainless steel), it is also highly reflective for laser processing.

The rougher the surface of the material, the higher the absorption rate of the laser; if it is sufficiently rough (even copper), it is not high-reflective for laser processing.

Method 3: Judging by surface state

The temperature of the surface of the material is different (solid, liquid), and the absorption rate of the same laser is different (high or not). In general, the higher the temperature or the liquid state of the surface, the higher the absorption rate of the laser. The absorption rate in low temperature or solid state is usually lower than that in liquid state.

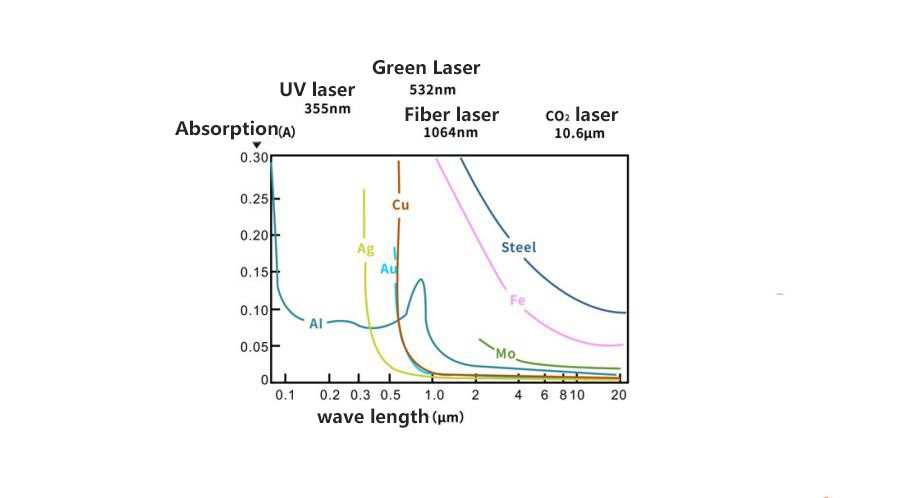

Method 4: Judging by the laser wavelength

For lasers with different output wavelengths; different materials exhibit different absorption rates (high reflective or no).

For laser processing (cutting, welding, etc.), the so-called high-reflective is only a relative concept, and it can be judged comprehensively whether it is high-refective processing by the resistivity of the material, the surface structure, the surface state, and the wavelength of the laser.