"Multiple, Quick, Good, and Gaving" in laser industry

Laser industry has the characteristics of "multiple, quick, good, and saving ", that is, "multiple application industries, fast processing speed, good processing effect, and low processing cost", especially with the promotion of myriawatt laser applications, The advantages of "fast, good, and province" are even more obvious. Today we take Maxphotonics 15000W as an example to fully demonstrate how laser can be "multiple, quick, good, and saving."

Multiple

With the development and maturity of myriawatt laser cutting technology, the thickness of laser-cut metal materials has gradually increased, and the processing range has continued to expand. It can process different metal materials including carbon steel, stainless steel, aluminum, brass, copper, etc. More diversified, the engineering scope of application is more extensive. This not only allows laser processing to be applied to more industries, but also enhances the market competitiveness of enterprises.

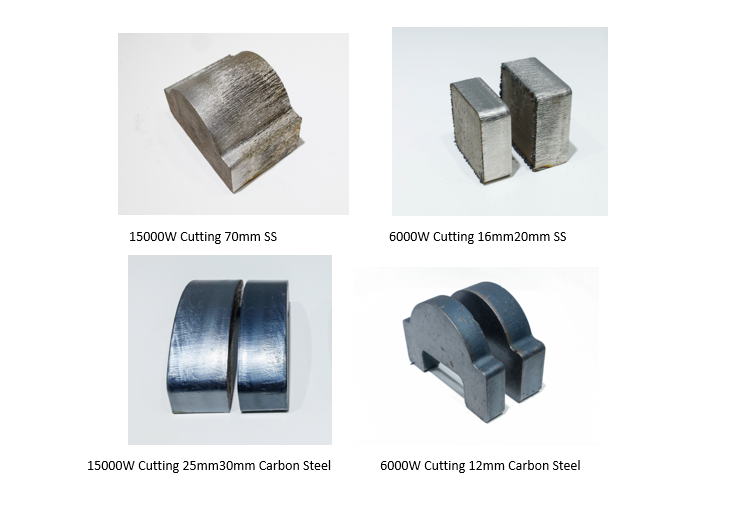

15000W Laser Cutting Samples

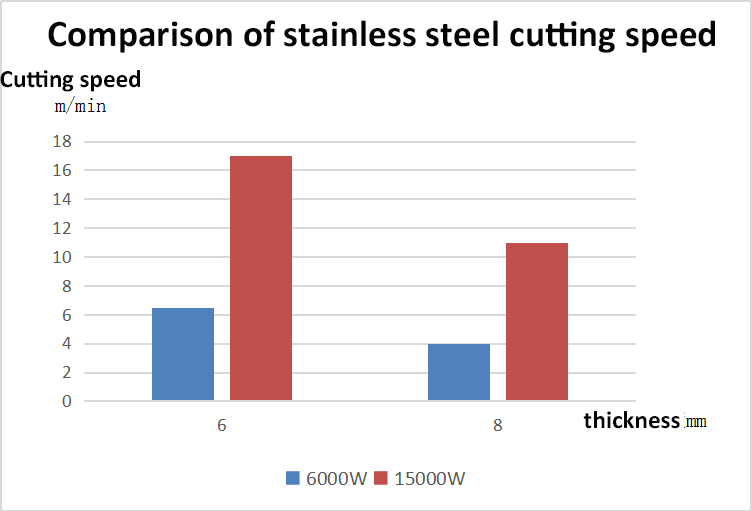

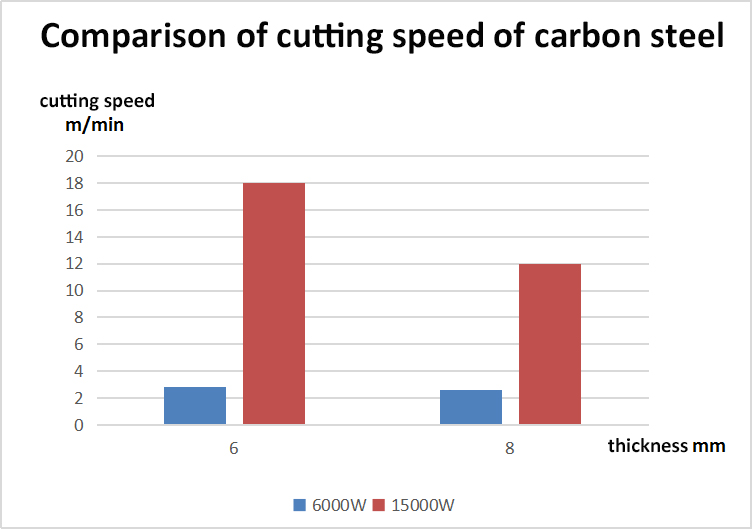

Quick

In this age of rapid development, time is money and efficiency is life. The fastest processing speed of myriawatt laser cutting can reach 100 meters per second, which is unmatched by traditional metal cutting and laser cutting below myriawatt, which saves time and labor costs.

Summary: Compared with 6000W, the efficiency of 15000W laser cutting stainless steel can be increased by 161% -175%;

Summary: Compared with 6000W, the efficiency of 15000W laser cutting carbon steel can be increased by 323% -507%;

Good

Good quality is the basis of the "existence" of the product. Cutting with a myriawatt laser not only greatly improves the processing efficiency, but also has a qualitative leap in the processing effect: larger cutting width, thicker cutting, brighter cross-section, and more tapered small.

| Cutting Capacity | 6000W | 15000W | |

| Carbon Steel | Stable processing | ≤25mm | ≤40mm |

| Sample cutting thickness | 30mm | 50mm | |

| Stainless Steel | Stable processing | ≤14mm | ≤25mm |

| Sample cutting thickness | 20mm | NONE | |

| Aluminium Alloy | Stable processing | ≤12mm | ≤22mm |

| Sample cutting thickness | 20mm | 50mm | |

| Brass | Stable processing | ≤12mm | ≤22mm |

| Sample cutting thickness | 20mm | 50mm | |

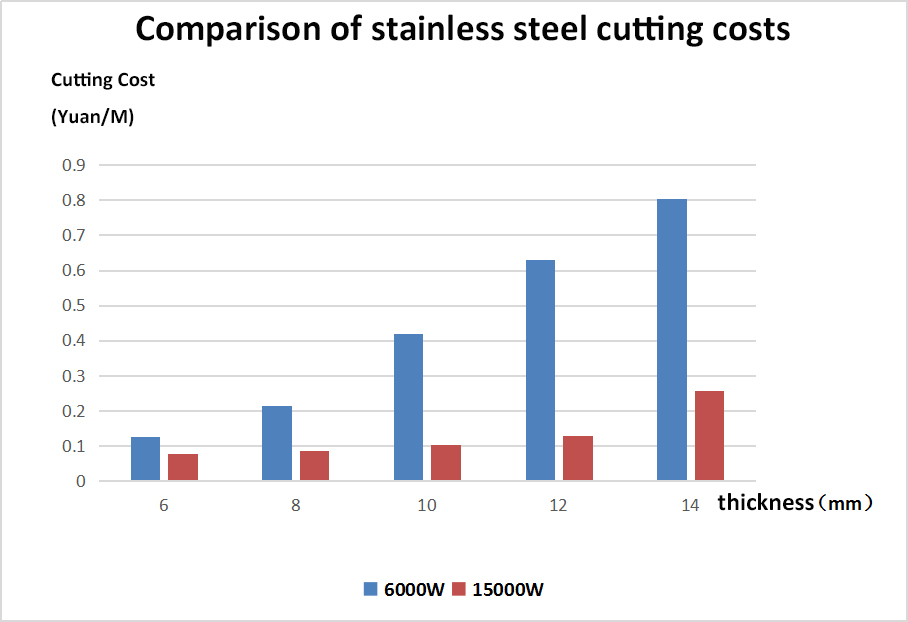

Saving

Cost management is the key to the development and profitability of an enterprise. In such a fiercely competitive market environment, companies must not only improve product quality to win customers, but also learn to reduce costs to gain more profitable space to maintain long-term stable development of the enterprise.

In recent years, myriawatt laser cutting has become more and more popular with end users. In addition to its wide processing range, fast processing speed, and good processing quality, there is also an important reason that it can save high-end operations for end users in the long run cost.

Summary: Compared with 6000W, the cost of 15000W laser cutting stainless steel can be reduced by 39% -80%;

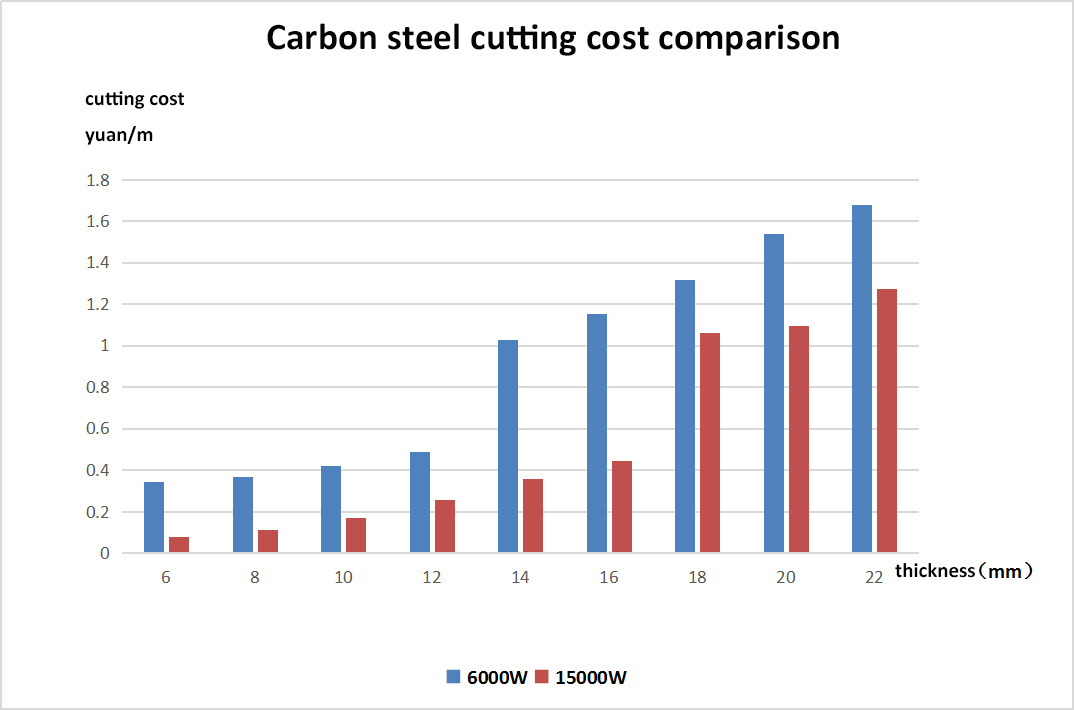

Summary: Compared with 6000W, the cost of 15000W laser cutting carbon steel can be reduced by 20% -77%.