In recent years, with the increasingly fierce competition in the consumer electronics market, the electronic product manufacturing industry has put forward higher requirements for products. The traditional processing method is easy to lead to unstable product quality, melted parts, difficult to form normal nugget, and low yield. The emergence of laser processing technology can quickly solve these problems for electronics manufacturers. In the production process of high-end electronic products, laser processing plays a major role in the volume optimization and quality improvement of the products, making the products lighter and slimmer and more stable. It is reported that about 70% of electronic product processing and manufacturing links are applied to laser technology (more than 20 different processes) and related manufacturing equipment.

At present, laser precision spot welding is mainly applied to electronic product housings, shields, USB connectors, conductive patches, etc. It has small thermal deformation, precise controllable action area and position, high welding quality, and can realize welding of dissimilar materials. Realize the advantages of automation. However, different welding methods are required when welding different materials.

According to the results of many experiments, Maxphotonics welding engineers have summarized how to use laser precision spot welding for different materials such as high-reflection materials, thin metal plates and dissimilar materials in the manufacturing process of consumer electronics. The best welding results.

1. Laser precision spot welding method for high reflectivity material

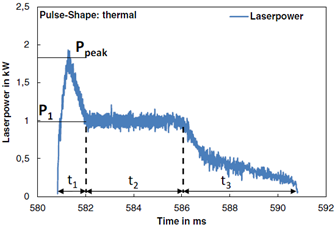

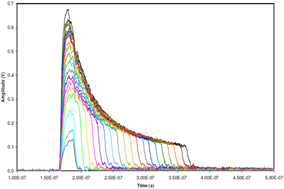

When welding high-reflection materials such as aluminum and copper, different welding waveforms have a great influence on the welding quality. By using a laser waveform with a pre-peak, it can break through the high reflectivity barrier. The instantaneous high peak power can quickly change the state of the metal surface and raise its temperature to the melting point, thereby reducing the reflectivity of the metal surface and improving the energy utilization. In addition, since materials such as copper and aluminum have a high thermal conductivity, the use of a descending waveform can optimize the appearance of the solder joint.

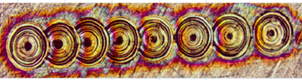

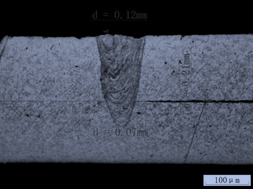

On the other hand, materials such as gold, silver, copper, and steel decrease the laser absorption rate with increasing wavelength. For copper, when the laser wavelength is 532 nm, the absorption rate of copper is close to 40%. Comparing and analyzing the characteristics of infrared laser and green laser, the infrared laser has a large spot size and a short focal depth. The copper has a low absorption rate. The green laser has a small spot size and a long focal depth, and the copper has a high absorption rate. Pulsed spot welding of copper with infrared laser and green laser was used respectively. It can be found that the welding spot size of the infrared laser is inconsistent, and the green laser has a more uniform solder joint size, uniform depth and smooth surface (Fig. 1-2). The green laser is more stable and the peak power required is less than half of that of the infrared laser.

Spike Waveform

1064nm Wavelength Welding Effect

532nm Wavelength Welding Wffect

2. Laser precision spot welding of metal sheet materials

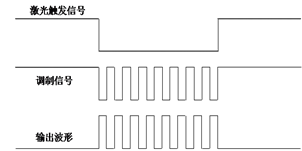

In the traditional millisecond laser, when the metal sheet material is welded, the material is easily broken down and the solder joint is large; while the high-reflective material has low instability due to its own instability and the laser in the solid state, the explosion often occurs when welding. Virtual welding and other phenomena. In order to solve the difficulties of thin plate and high anti-metal welding, by performing analog and digital modulation on the QCW/CW mode of the fiber laser, one pulse output can be realized once, and single-point multi-pulse welding can be realized with less power.

Modulation

High frequency pulse spot welding surface forming

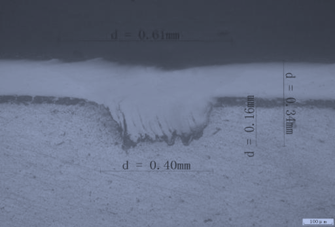

Seam Section

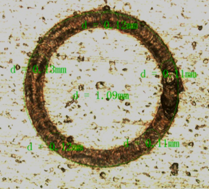

3. Laser precision spot welding of dissimilar materials

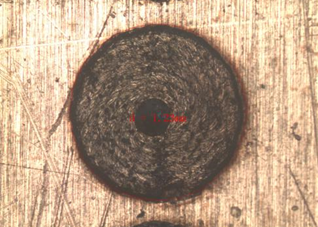

When welding laser dissimilar materials, it is prone to problems such as weak soldering, cracking, and low joint strength. This is because the physical properties of the two are different, the mutual solubility is low, and brittle compounds are easily formed. These compounds make the welding head mechanics. Performance is greatly reduced. The high-beam quality nanosecond laser is used to control the formation of intermetallic compounds by high-speed scanning, precise control of heat input, to achieve splicing of dissimilar metal sheets, and to improve weld formation and mechanical properties.

Output Waveform

Scanning Method

Weld Surface Molding

Weld Section

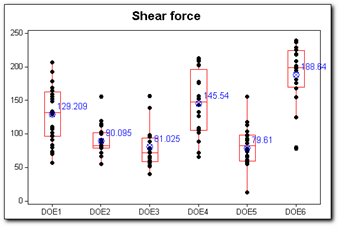

Welding strength test of 316L stainless steel and 6063 aluminum alloy

Maxphotonics's quasi-continuous fiber laser and MOPA pulse width tunable pulsed fiber laser have become the ideal light source for laser precision spot welding because of its high beam quality, high peak power, adjustable controllability and so on.

150W/1500W quasi-continuous fiber laser

The product has various compatibility and control modes, which can switch between pulse and continuous mode, and simultaneously handle the processing tasks of two different lasers at the same time. The pulse width waveform is flexible and adjustable, the heat dissipation is fast, and the electro-optical conversion rate is over 30%, which is the long pulse width. Another option for high peak power applications.

120W MOPA pulse width tunable pulsed fiber laser

The pulse width tunable pulsed fiber laser uses MOPA to construct a two-stage amplification with independently adjustable pulse width and frequency, making more laser applications possible. The pulse width is flexible and adjustable from 60 to 350 ns, the peak power is up to 10 kW, the repetition frequency is up to 1000 kHz, and the self-developed online isolator is the ideal laser source for laser fine processing.