With the development of laser processing technology, high-power, high-brightness semiconductor lasers have gradually emerged as the next-generation laser source together with fiber lasers, ultra-fast lasers, and disc lasers, making many important applications possible.

Compared with other lasers, high-power semiconductor lasers have incomparable advantages. They have small structure, simple structure, stable system, long service life, uniform energy distribution, high photoelectric conversion efficiency, high light absorption rate of metal materials and The realization of automation and other characteristics, has been widely used in the processing of metal materials.

Application of high power semiconductor laser in welding

High-power semiconductor lasers have been widely used in the welding of metal materials due to their excellent performance. Due to its large spot size, uniform beam quality distribution and high absorption rate of metal materials, the molten pool is stable during the welding process, without splashing, and the surface of the weld is smooth and beautiful. It is suitable for metal sheet welding, such as life hardware, mechanical products and auto parts. welding.

1.Laser spot welding and laser seam welding

Maxphotonics 1500W semiconductor laser spot welding process is thermal conduction welding, welding metal material by adjusting laser power and radiation time. Due to the uniform distribution of the spot energy, a slow gradient of the laser energy can be achieved, thereby solving the problem of porous porosity caused by the collapse of the pseudo-lock hole at the end of the spot weld.

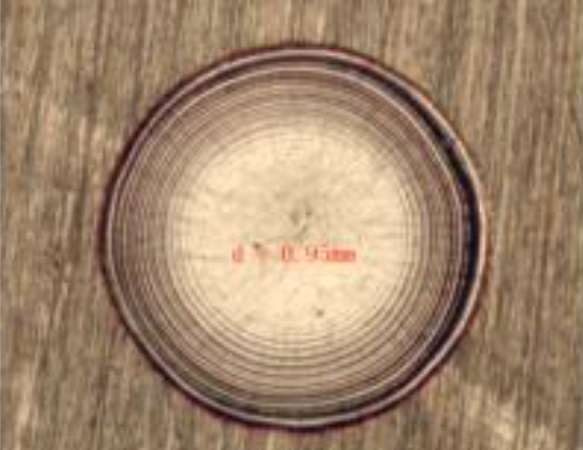

Stainless steel spot welding

2. Laser continuous welding

Maxphotonics 1500W semiconductor laser can form keyhole effect in continuous welding process and has strong penetrating power. In continuous thermal welding, the welding process is stable, the surface is smooth, the appearance is beautiful, and the weld cross section is semi-circular, which can realize the welding of metal thin plate structural parts (butt welding, lap welding, fillet welding, etc.), the weld width can reach 3.5mm; in continuous deep-fusion welding, the welding process is stable, no splash, and the weld cross section is Y-shaped. The post-weld strength can meet the requirements of the workpiece.

3. Double beam laser welding

Maxphotonics 1500W semiconductor laser is combined with MFSC-1500W single-mode continuous fiber laser to achieve different weld cross sections (semicircular, V Shape, U Shape, Y Shape) through different laser energy ratios. The capping welding of the new energy power battery case and the package soldering of the filter.

Semiconductor laser welding application case

Semiconductor laser product advantages

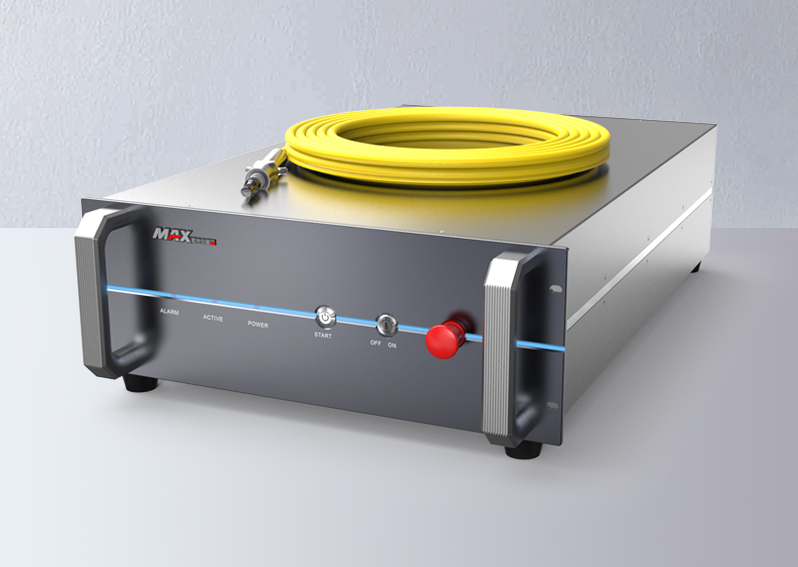

Maxphotonics also has a large R&D investment in high-power semiconductor lasers. Currently, 1500W high-power semiconductor lasers which have higher electro-optical conversion efficiency, more compact size and more competitive price than fiber lasers.

The laser module is small in size, light in weight and simple in structure;

The laser system is stable and has a long service life of over 30,000 hours.

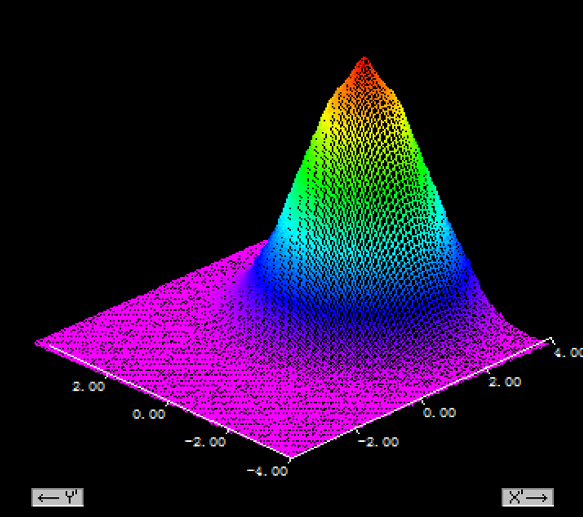

The energy distribution is even;

The photoelectric conversion efficiency of up to 65%;

The wavelength is shorter (915 nm), and the light absorption efficiency of the metal material in this band is higher.

Maxphotonics 1500W energy distribution chart