The good tool for lithium battery manufacturing-laser cutting tabs!

With the vigorous development of the new energy industry, the demand for lithium batteries has increased dramatically. The survey shows that China's total lithium battery shipments in 2018 were 102GWh, a year-on-year increase of 27%. The shipment of power lithium batteries was 65GWh, an increase of 46% year-on-year. It accounted for 63.7% of total lithium battery shipments, increase of 8.3% over 2017.

Facing the development needs of the commercialization of power lithium batteries in the new energy era, major manufacturers are eager to find a solution that can fundamentally "improve quality and reduce costs" in order to break through the limitations of existing manufacturing and processing technologies . Among them, in the processing of power lithium batteries, the bottlenecks of traditional hardware die-cutting technology have become increasingly prominent, including problems such as low processing efficiency and poor application flexibility, which have been unable to meet the development requirements of intelligent manufacturing. Lasers tab cutting technology has become a new way to reduce the production cost of power lithium battery tabs and improve product stability.

Comparison of advantages and disadvantages of tab cutting

| Comparison of cutting methods of power lithium battery tabs | ||

| Cutting method | Advantage | Disadvantage |

| Laser cutting | ·High cutting efficiency ·Low maintenance costs and no consumables ·Flexible cutting shape, size and spacing ·Flexible adjustment of laser parameters for different tab materials and thicknesses ·One device is compatible with multiple tabs | ·High one-time investment cost |

| Traditional Die-cutting | ·Low one-time investment cost | ·Tool wear, need to be replaced regularly ·Long mold replacement time ·The cutting shape is relatively limited, and adjustment is troublesome ·Restrictions on cutting tab material |

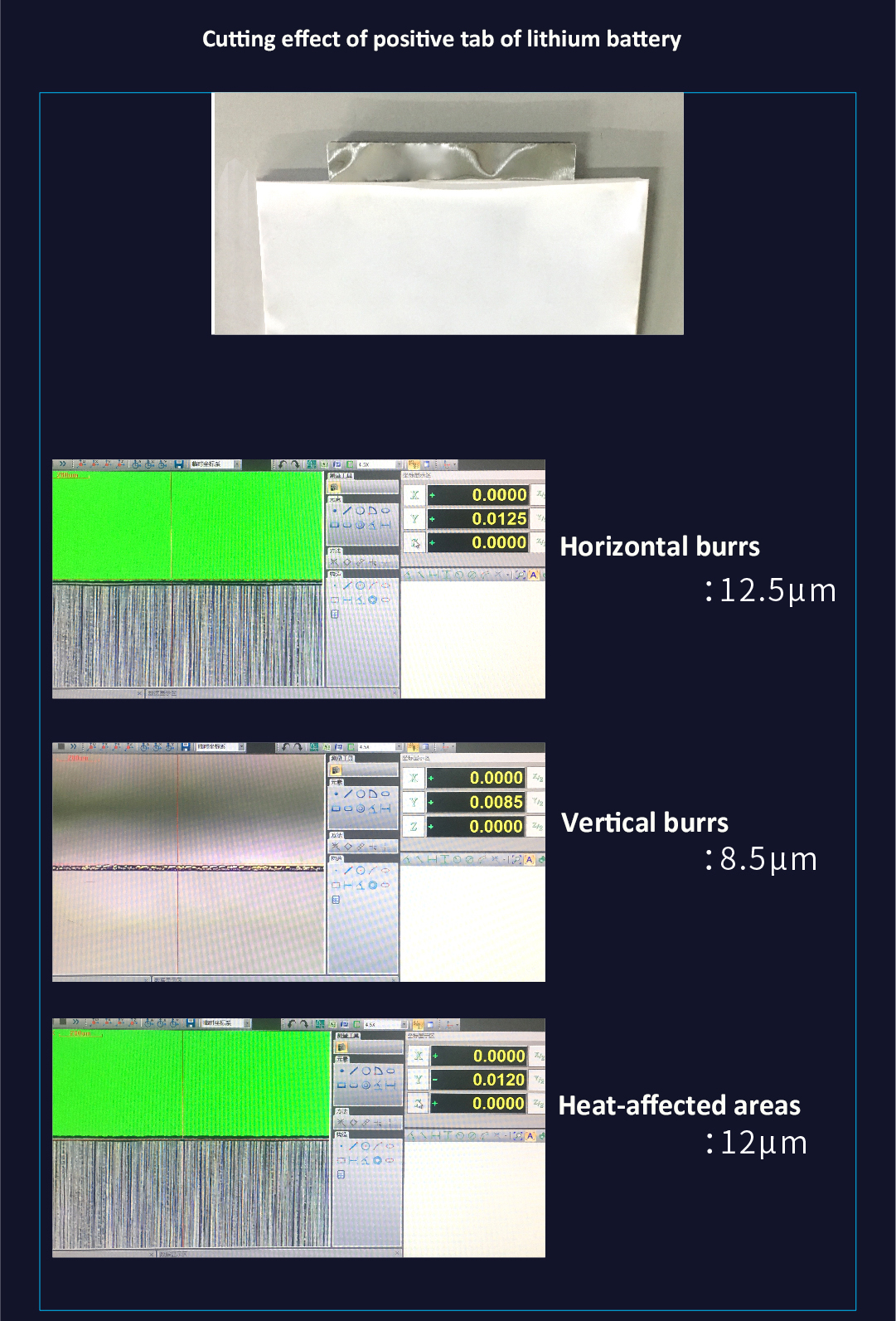

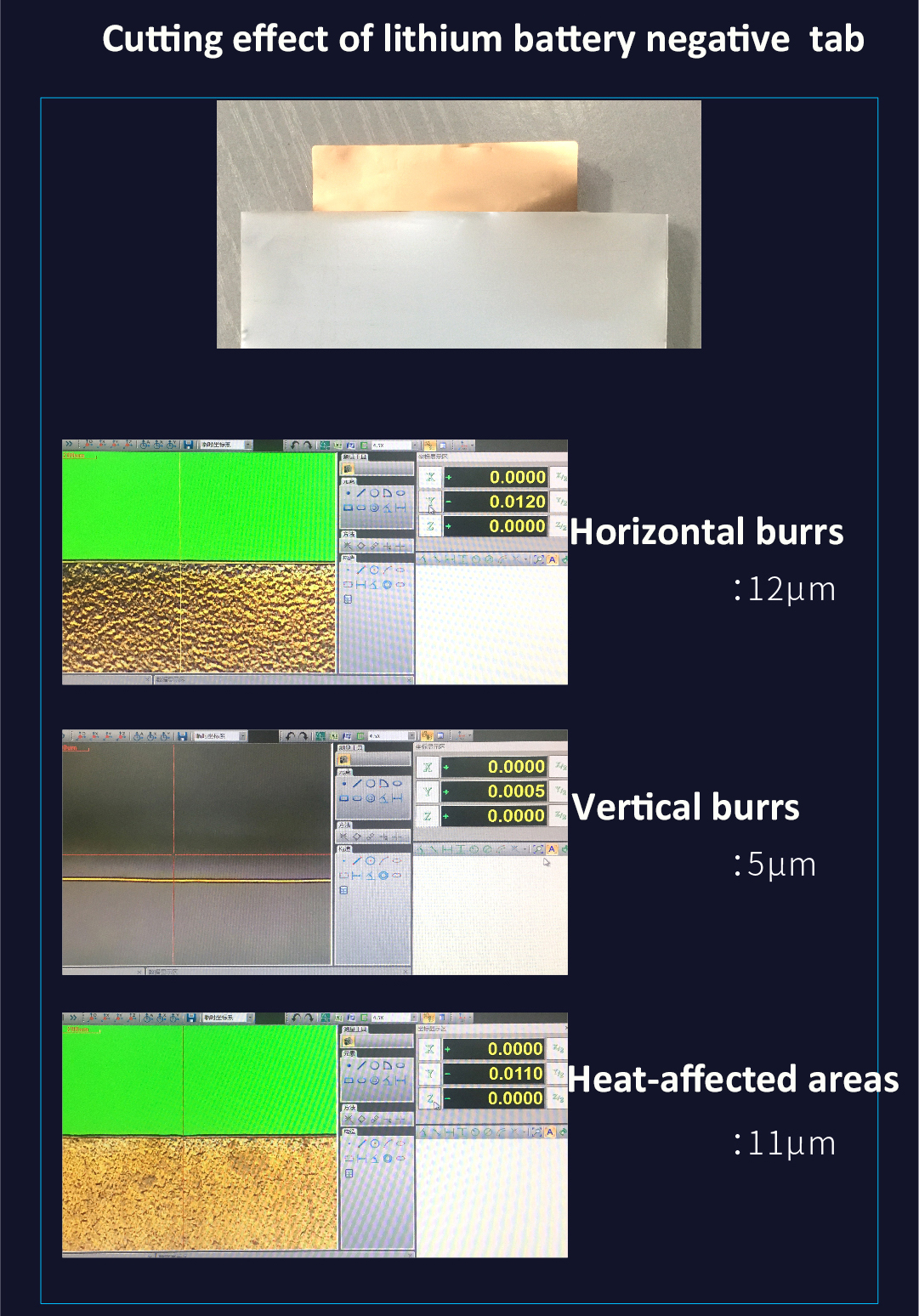

Tab laser cutting effect

When laser cuts positive and negative tab on the lithium battery pole piece, the cutting effect will directly affect the safety of the lithium battery. Excessive cutting burrs, heat-affected areas, and metal leakage areas may affect the performance of lithium batteries. For different electrode sheet materials, different laser cutting process parameters need to be adjusted.

| Cutting material of power lithium battery tab | ||

| Power lithium battery pole piece | Material | Cutting effect evaluation parameters |

| Positive | Aluminum foil, (ternary material, lithium iron phosphate, lithium manganate) | burrs, heat-affected areas |

| Negative | Copper foil, graphite | |

It can be seen from the cutting effect that the vertical burr of the laser cutting pole ear is less than 10um, the horizontal burr is less than 15um, and the heat affected zone is less than 15um. These process defects are strictly controlled, which greatly reduces the safety risks of lithium batteries.

Laser Cutting for Power Lithium Battery Tab

| Laser Cutting for Power Lithium Battery Tab | |

| Laser Model | Parameter |

| MOPA Fiber Laser | Good beam quality Adjustable pulse width: 30-200ns High repetition frequency High power (100-500W) |

| Single Module Small Fiber Core CW Fiber Laser | Good beam quality Small fiber core diameter, high focusing energy density High power (500-1000W) |

For fiber lasers, one of the important parameters is the beam quality M2. The beam quality directly determines the best effect of a fiber laser. Therefore, improving the beam quality is an important task for tab cutting .

So far, 100W pulse fiber laser is commonly used for tab cutting . Maxphotonics has designed a MOPA fiber laser MFPT-200M for tab cutting process in the lithium battery industry. It has high cutting efficiency and is compatible with more pole ear materials and thickness cutting.

Maxphotonics MFPT-200M Fiber Laser

The single-module continuous fiber laser is used to cut tabs, and with smaller burr and heat affected zone . Maxphotonics MFSC-1000W uses a thin fiber core diameter output, good beam quality, high focusing energy density, and has the advantages of thicker cutting ear material and faster cutting speed.

Maxphotonics MFSC-1000W CW Fiber Laser