Which laser cutting equipment is more cost effective

With the popularity of laser cutting equipment, competition in the laser processing industry is becoming increasingly fierce. How to improve efficiency and reduce costs has become a concern for most users. Today, we take 6000W laser cutting equipment and 12000W laser cutting equipment as examples. From the aspect of processing cost and processing efficiency, we will calculate which type of laser equipment is lower in cost.

Processing cost

The following cost analysis is calculated according to the following configuration parameters:

| Laser Cutting Electricity fees | Air compressor Electricity fees | Auxiliary Gas cost | ||

| Laser Cutting | Cutting machine total power consumption | 3Mpa Air compressor total power consumption | Oxygen | Nitrogen |

| 6000W Laser Cutting | 38kW | 15kW | ①Oxygen consumption according to:6m³/Hr ②Cost is calculated according to2.9元/m³ | ①Nitrogen based on air pressure 10-20bar, Air consumption according to:25-35m³/Hr ②Cost is calculated according to 2.5 yuan / m³ |

| 12000W Laser Cutting | 68kW | 15kW | ||

| Industrial electricity costs at 1 yuan / kWh | ||||

| Note: Since the small parts such as nozzles and lenses will be used differently according to different users, and they account for a small portion of the total processing cost, this cost is not calculated. | ||||

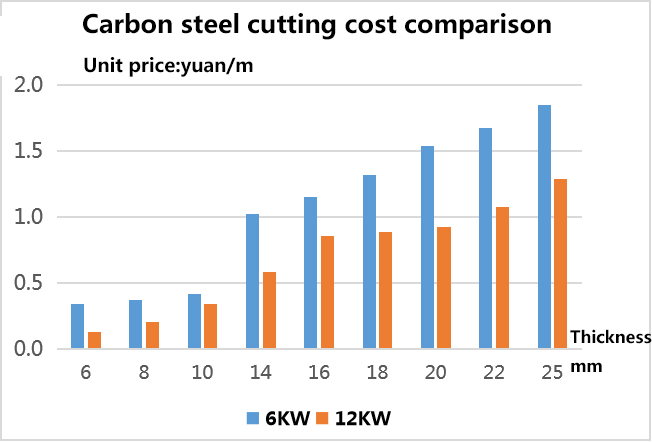

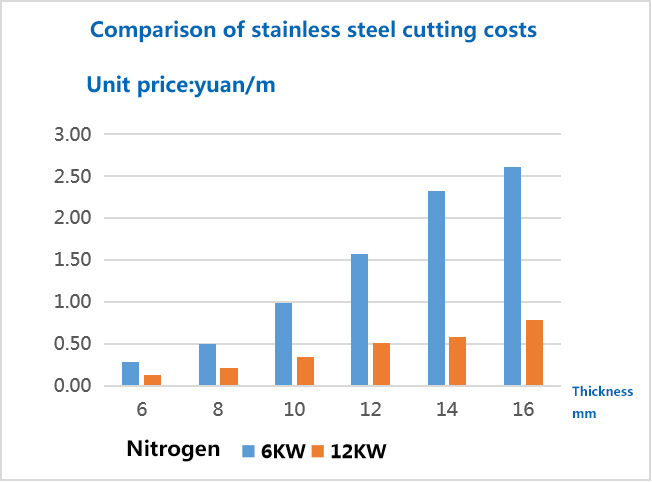

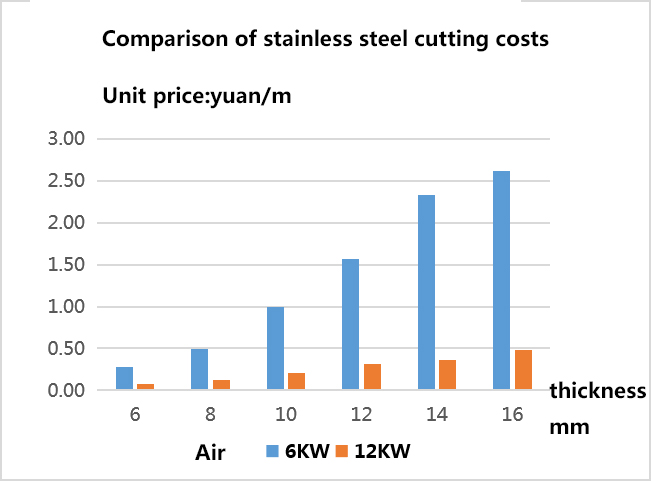

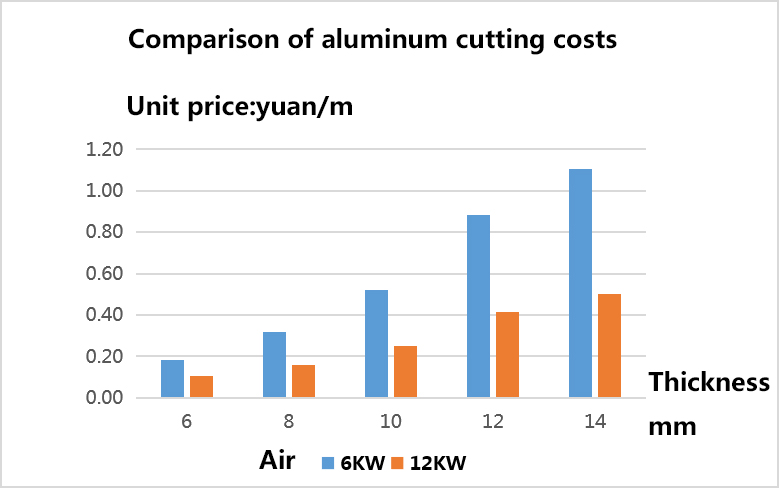

| 12KW and 6KW Laser cutting processing cost comparison | |||

| Material | Thickness | Auxiliary Gas | Proportion of 12KW to 6kW processing cost reduction |

| Carbon Steel | 6-14mm | 6kW:Oxygen 12kW:Nitrogen | 43%-63% |

| 16-25mm | Oxygen | 25%-40% | |

| StainlessSteel | 6-16mm | Nitrogen | 55%-75% |

| Air | 72%-85% | ||

| Aluminium | 6-14mm | Air | 43%-55% |

From above data: Compared with the 6KW laser processing cost, the 12kW laser cutting cost can basically be reduced by more than half. Among them, stainless steel has the largest advantage, followed by carbon steel and aluminum. Air is used as an auxiliary gas when cutting stainless steel, and the unit price processing cost is the lowest, which can meet products with low requirements on cutting end faces.

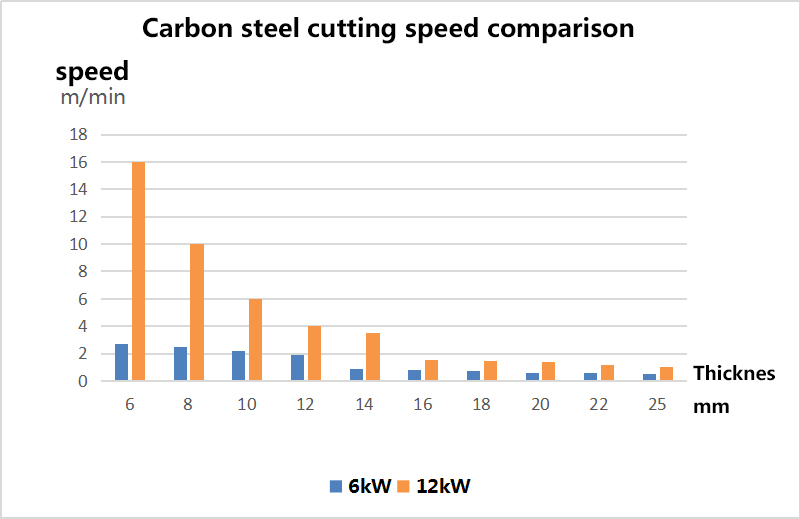

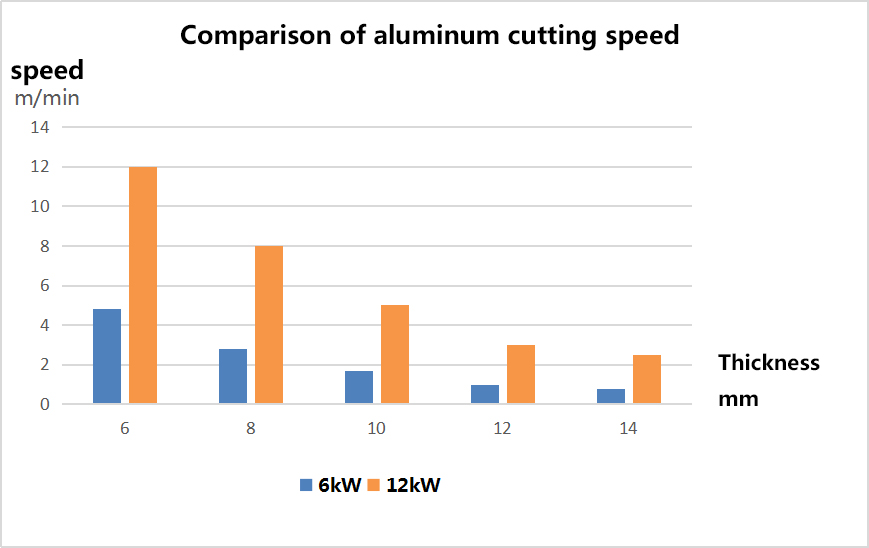

Processing Efficiency

From the test cutting speed, it is concluded that when cutting carbon steel, the 12kW laser cutting speed is 87% -493% faster than the 6kW laser cutting speed; when cutting stainless steel, the 12kW laser cutting speed is faster than the 6kW laser cutting speed 163 % —289%; When cutting aluminum, the speed of 12kW laser cutting is 150% -213% faster than that of 6kW laser cutting.

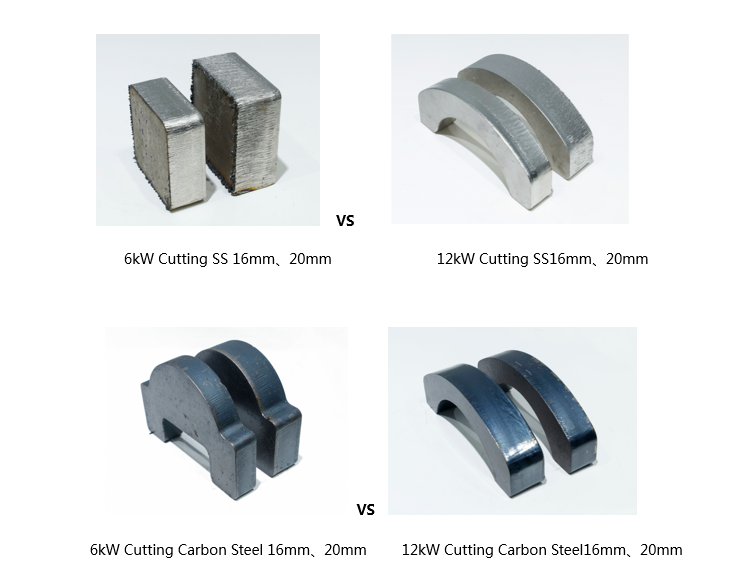

Processing Effect

| Processing cost | Processing Efficiency | Processing Effect | |

| 6kW Laser Cutting | 12kW laser cutting cost is more than 50% lower than 6kW | 12kW laser cutting speed is 87% -493% faster than 6kW | Cutting stainless steel 16mm, 20mm with more slag; Carbon steel 16mm, 20mm can only cut out matte surface with large taper . |

| 12kW Laser Cutting | Cutting stainless steel 16mm, 20mm with almost no dross; Carbon steel 16mm, 20mm can cut a smooth and bright surface, and with small taper . |

6kW CW Fiber Laser

12kW CW Fiber Laser

In terms of overall economic benefits, the price of 12kW laser cutting device is 30% -40% higher than that of 6kW laser cutting device, but the production efficiency is more than several times that of 6kW laser cutting device, and the processing cost is also higher than that of 6kW laser cutting device. The equipment is reduced by more than half, which greatly reduces the processing time and processing cost of a single workpiece, and the processing effect is more excellent, which can create a multiplier effect for users.

Of course, specific problems need to be analyzed in detail. Users need to purchase processing equipment and choose the processing method that suits them according to the actual needs of their enterprises.